During the lifetime of Robohub Eindhoven, multiple robots have been developed for various purposes. which you can see below

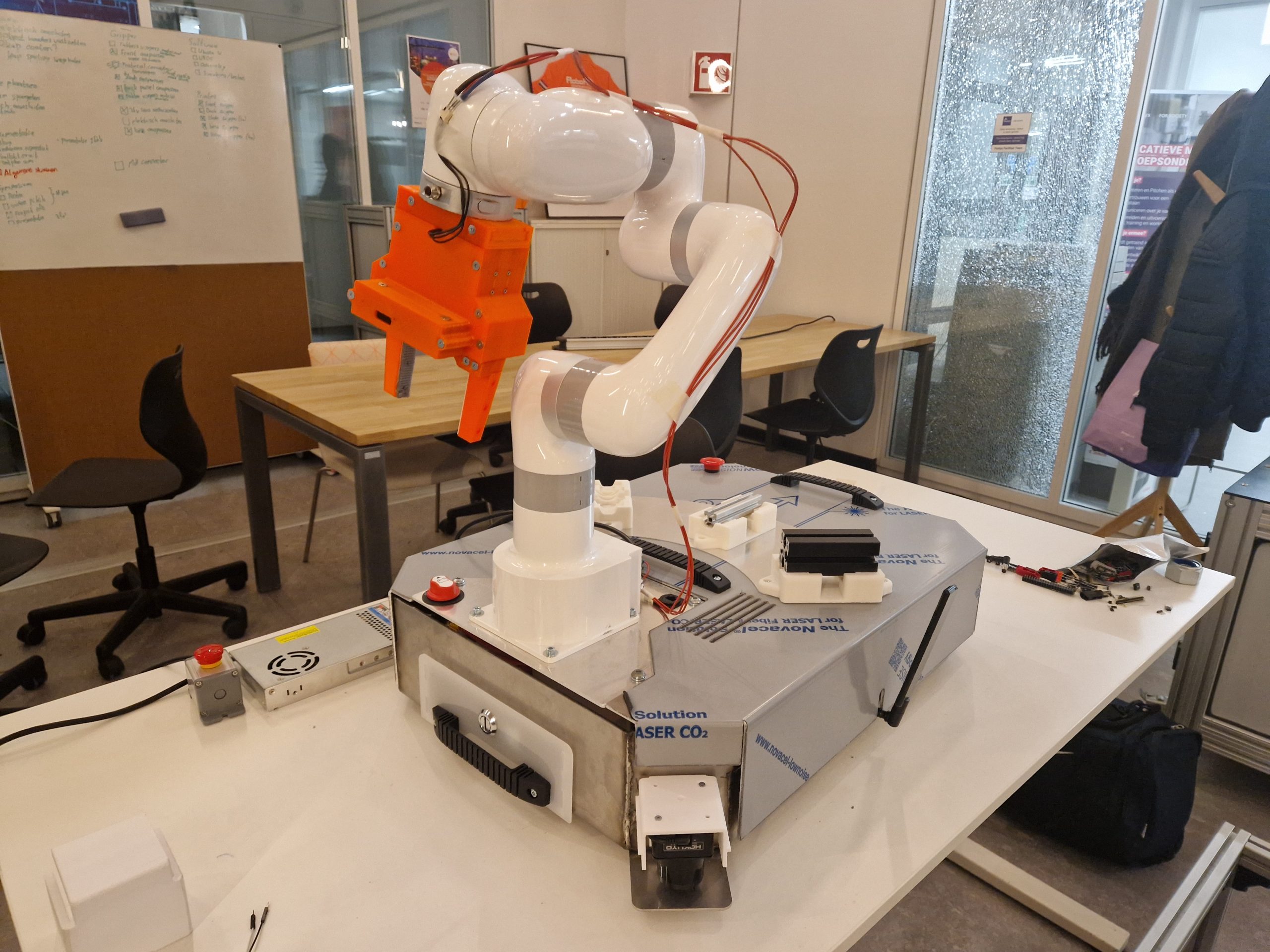

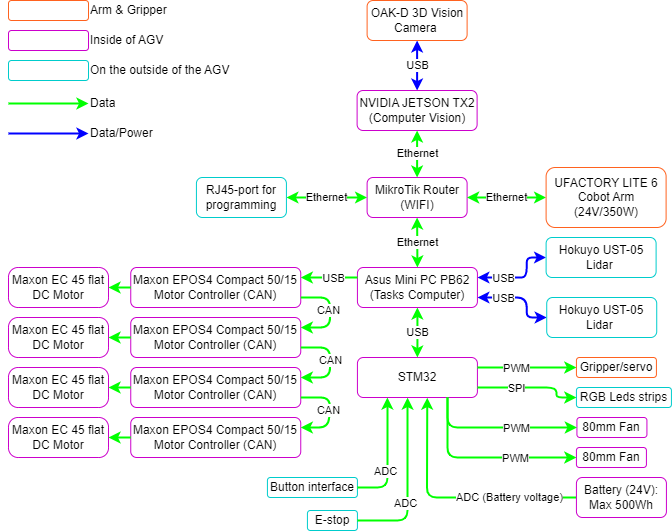

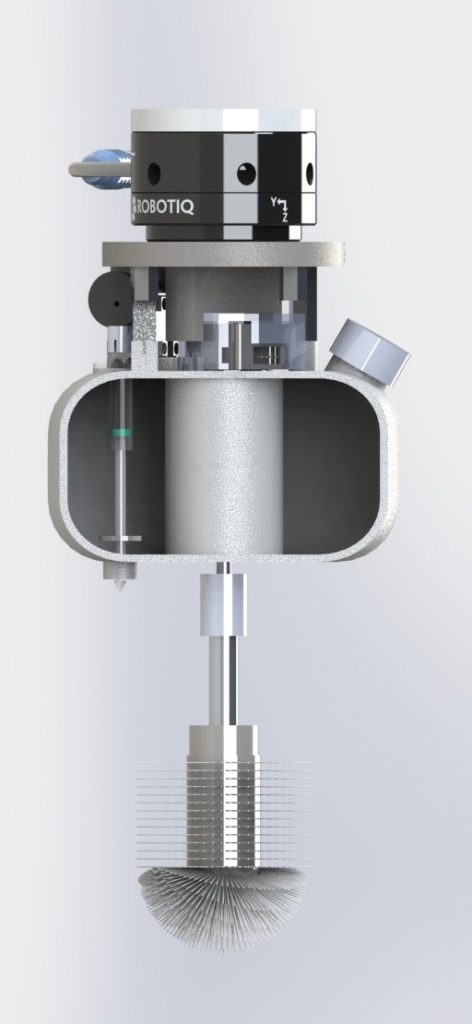

SLICK

SLICK is the newest robot from Robohub Eindhoven for the Robocup@work league. It is an autonomous vehicle that can recognize, detect and manipulate objects from A to B. It has an integrated 3D vision camera built into the gripper. The Hardware architecture is shown below:

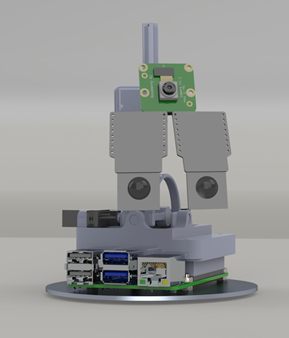

SUII (Sui2)

Second self-built robot and current competition robot

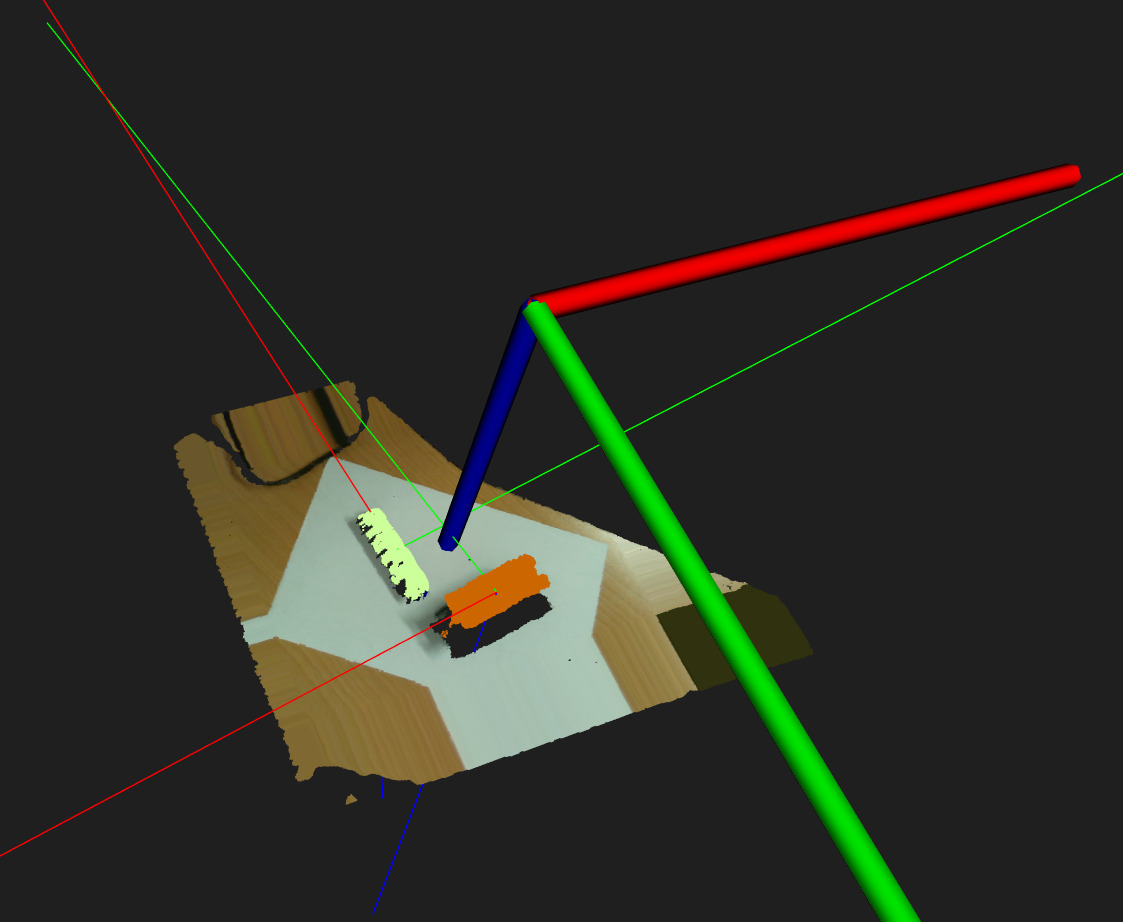

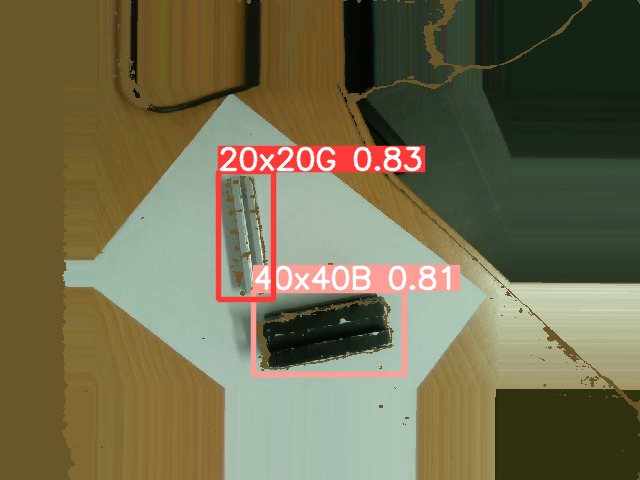

Sui2 is a robot consisting of an AGV (Automated Guided Vehichle), robot arm and deep learning based vision system. Sui2 is built to transport objects between different workstations in an industrial working environment completely autonomously. For example, Sui2 can drive autonomously to the workstation where an object needs to be picked up. When Sui2 has driven to the right location, it uses a computer vision system to detect and locate the correct object. When the object is localized, the object can be picked up and taken to the correct workstation. Suii is used by RoboHub Eindhoven to participate in RoboCup@Work competitions. At the RoboCup@Work competition the robothas to complete tasks as described above. During the 2019 RoboCup@Work competition we got an amazing 5th place during the world championships! Next to the RoboCup@Work competition Sui2 also is used for demonstration purposes at events.

Suii uses two laser scanning rangefinders for localization and object avoidance. The two laser scanner provide a 360 degrees field of view around the robot. In this way Suii can see objects in all driving directions. This is important because Suii is a holonomic robot, this means that Suii can drive in all directions without turning. This is possible due to the special mecanum wheels that Suii has.

For manipulating objects Suii uses a Universal Robots UR3 robotic arm in combination with a custom made gripper. The UR3 robotic arm is a so called “cobot”, this means that the UR3 has some extra safety measures compared to “normal” industrial robotic arms. Because these extra safety measures it’s safe to use without a robot cell in the neighbourhood of people. To fit the UR3 on the AGV, the original electronics enclosure is changed by a smaller custom built electronics enclosure. At the end of the UR3 robotic arm a custom gripper is mounted for picking objects. A camera is built into the gripper, that is used for Two LED strips are mounted on the gripper to create consistent lighting conditions for the camera.

Suii uses the camera to detect and localize objects that have to be moved. For detecting the object a convolutional neural network is used (CNN). The CNN can detect objects in real time, and give a rough estimation of the location of the object. After the object detection by the CNN, a more traditional computer vision algorithm calculates a more accurate position and rotation of the object.

For more technical information hardware and software wise about Suii have a look at RoboCup Team Description paper down below:

Faraday

First self-built robot

Faraday is an AGV built by Robohub enhanced with the UR3 robotic arm and a gripper used for the Robocup@work 2018. Its origin is quite a chaotic story… Originally we tried to compete at the Robocup@work league with the “Kuka Youbot” which was the standard platform used by all teams. As traumatising as it was, a driver in the robot did brake shortly before the competition. There were no reserve components available as this platform had reached its end-of-life. Robohub – being the only applied science university competing at the competition – decided to not give up but to start an innovation which hadn’t been done before at that time within the competition: “building our own AGV suitable for the league”.

After a lot of late hours of: designing, finding sponsors and producing the robot, Faraday was born. We did compete at the qualifications of 2018 with our robot which did quickly receive the nickname “Frankenstein” due to its lack of cable management and bulkiness. But one who doesn’t get pulled back by criticism will succeed. We proofed that our robot did work and did score points during the competition and we even got invited to the world finals in Toronto Canada because of our new approach in innovating the league. We did reject this offer in order to fully focus on develop Faraday’s successor: “SuII”.

After the creation of Suii, Faraday has been used as a modular AGV for research purposes and to test our navigation software. Faraday was later deconstructed and used as a donor for a new big RoboHub project “Lau” an autonomous Toilet cleaning Robot. The soul of Faraday is still alive within our portfolio. It’s an amazing, educational and not to forget a hectic memory.

Kuka Youbot

Robocup@work standard platform

The Kuka Youbot is a holonomic robot with an integrated robotic arm which is the most used robot in the RoboCup@work competition. The robot is made by the company Kuka. The driver of our Kuka robot died while the production of this 10-year-old model has stopped, hence innovation was required. Faraday and Sui² are its successors.

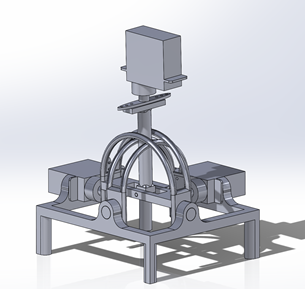

Lau

Autonomous toilet cleaning robot

The robot Lau is a redesign based on components from our old robot Faraday, which is designed to compete in the yearly Delta Advanced Automation Contest. For this competition we designed a AGV which can autonomously clean the inside of a toilet. A group of 4th year engineering students designed and built the robot. At the end of the half year long project the group presented Lau and won the grand prize in the mechatronics category at the Engineering & Technology in practice symposium, hosted by Fontys centre of expertise HTSM.

The Delta advanced automation contest is a yearly open innovation contest hosted by Delta Electronics. Delta Electronics is a Taiwanese electronics manufacturing company which focusses on power electronics, automatization, infrastructure and automotive. The goal for the competition is to invent, design and built a robot that automates or executes a task based on parts from Delta Electronics. Lau is heavy duty AGV which can carry loads of over 200kg. The robot is equipped with a Delta DRV70L robotic arm which has a built-in control box and has a reachability of 700mm. Lau has a maximum speed of 1 m/s and it includes a clever ‘suspension’ mechanism which makes sure to have optimal grip at uneven surfaces. Furthermore, it has 2 Hokuyo LiDAR scanners for 360 degrees Field of View for navigation.

It also has a custom-made end effector which is designed and built from 3D printed parts and can dispense the needed chemicals to properly clean the inside of the toilet.

The competition was unfortunately canceled during the competition. After this, we pulled the plug on the project and put our full focus back towards the robocup@work competition.

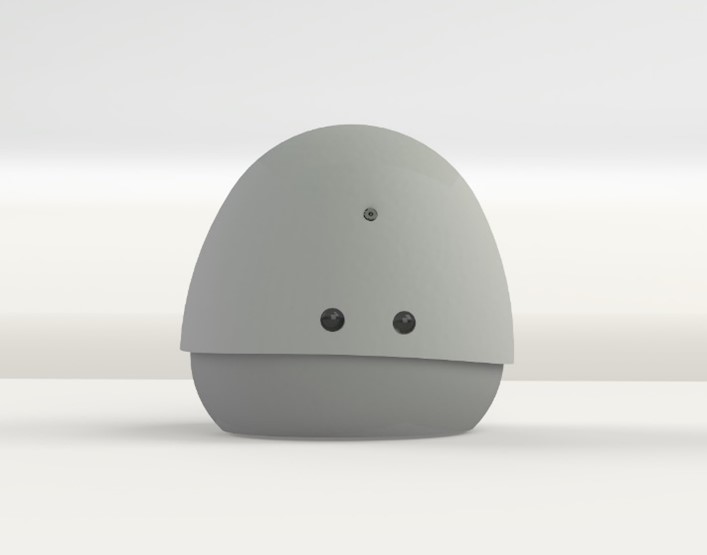

Mira

Human interactive robot

Mira is a robot designed by RoboHub Eindhoven in cooperation with Fontys Centre of Expertise HTSM. This robot is inspired by the Mira that’s created by Pixar 3D artist Alonso Matrinez. Mira is meant as a little friend for kids and disabled people in hospitals and care homes. Mira has several ways to interact with people and express feelings. For example, Mira has a camera, speaker, moving head, eyes and a multi color lamp.

With the combination of the camera and moving head, Mira can track faces and objects. Mira has a clever mechanism for moving its head. This small mechanism enables rotation of the head around three rotation axes.